ENG / 中文

Tall Frame Rockwell/Superficial Rockwell Hardness Tester/Large Twin Digital Rockwell Hardness Scales

Model No. 900-384TB

Features

The NEW! Phase II Tall Frame 900-384TB twin rockwell hardness tester can be used directly to measure Rockwell hardness and superficial Rockwell hardness and change those values of Rockwell hardness into other rockwell hardness scales, HB, HV, HLD, and HK values.

Features:

The NEW! Phase II Tall Frame 900-384TB twin rockwell hardness tester can be used directly to measure Rockwell hardness and superficial Rockwell hardness and change those values of Rockwell hardness into other rockwell hardness scales, HB, HV, HLD, and HK values.

Loaded with features such as ultra precise measurements, wide measuring range, automatic main test force loading/unloading, digitally displayed results, etc. Utilizing the guidelines of ASTM E-18 ,the 900-384TB rockwell hardness tester is suitable for hardness testing on carbon steel, alloy steel, cast iron, non-ferrous metal and engineering plastics. A perfect performer suited for any environment including heat treat facilities, tool rooms, workshops, laboratories and inspection labs.

For full conformance to the latest E18-20 specification, please call (201) 962-7373

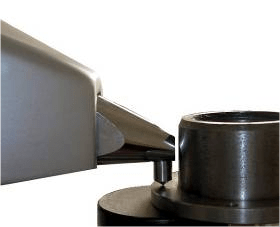

- The protruding indenter design is ideal for testing inside diameters and recesses, often impossible with more traditional hardness testers. Inside diameters as small as 1-1/2-inches can be tested with the standard indenter. Operators can test close to vertical surfaces, to within 1/4-inch with the standard indenter. Testing is fast, accurate and there are fewer broken diamonds due to an outstanding viewing area.

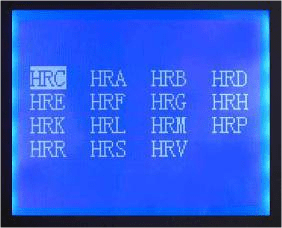

- Wide measurement range: 30 Rockwell hardness scales in total, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y and HR45Y.

- Auxiliary functions: The 900-384TB Rockwell hardness tester is capable of upper and lower limit settings; data statistics, the computing for average value, standard deviation, maximum and minimum; scale conversion (the testing results can be converted into the values of other Rockwell scales, HB, HV, HLD, and HK. Curved surface correction will automatically correct the measuring results for cylindrical surface and spherical surface.

Specifications for twin rockwell hardness tester:

| Minor Load | 3 Kgf, 10 Kgf |

|---|---|

| Major Load | 15Kgf 60 Kgf 30 Kgf 100 Kgf 45 Kgf 150 Kgf |

| Test Force Application | Load cell |

| Test Force Control | Motorized |

| Display | Hi Def LCD Digital Readout |

| Display Resolution | 0.1HR |

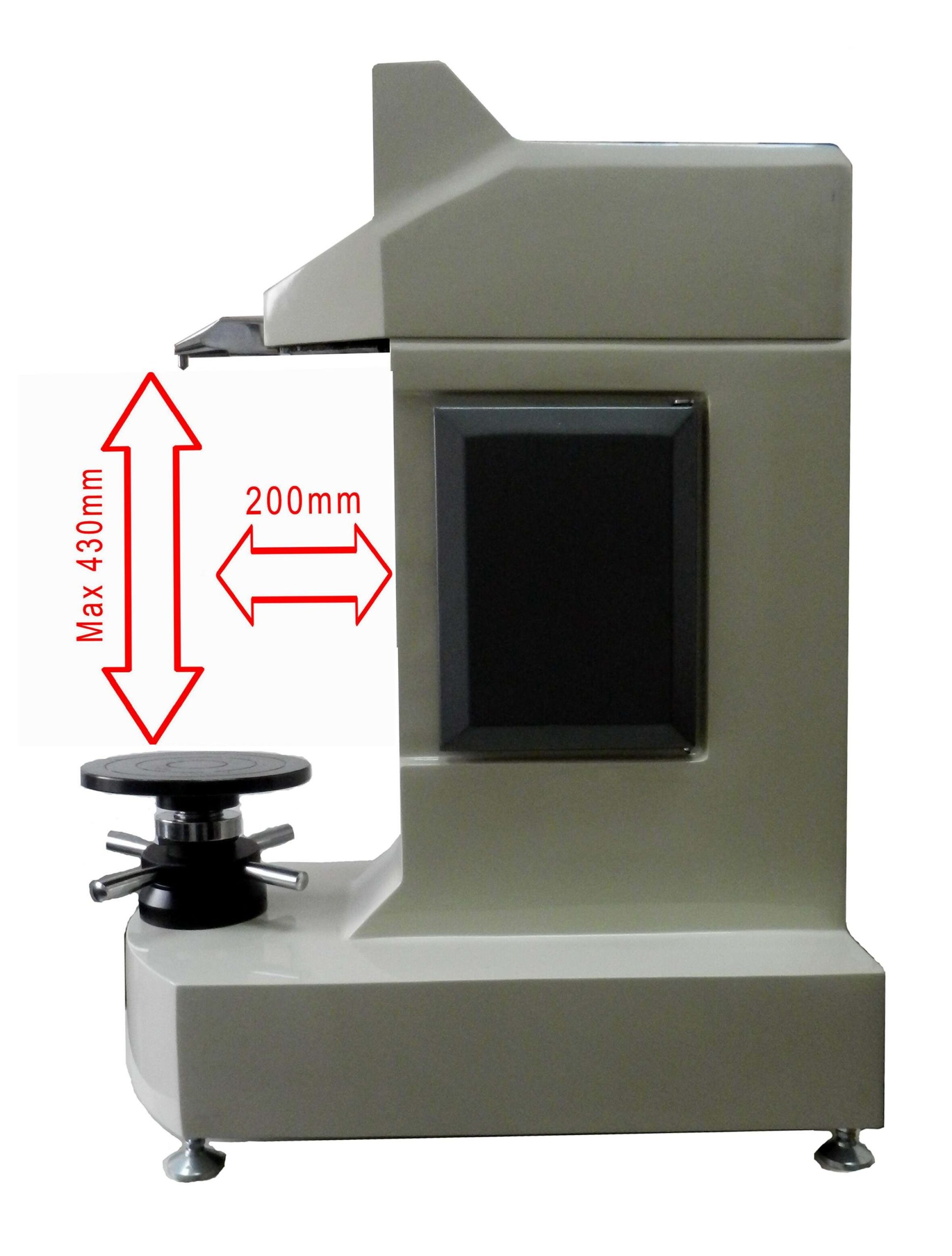

| Vertical Capacity | 16.9″ |

| Memory/Output | 500 Tests/USB |

| Throat Depth | 7.8 in. |

| Power Supply | single phase, AC, 110V/220V(selectable) |

| Weight | 285lbs Net (Shipping weight = 350 lbs) |

| Dimensions | 285lbs Net (Shipping weight = 350 lbs) |

Standard Accessories:

- C-scale Diamond Indenter

- 1/16″ Ball Indenter

- Built-in Mini Printer

- Test Table 5.87″ (150mm)

- Flat Anvil 2.5″ (63mm)

- Std. Vee Anvil

- Accessory Case

- Dust Cover

- 3 piece-HRC test blocks

- 1 piece-HRB test block

Options:

- NIST/ASTM certified hardness test blocks, penetrators and kits are available.

- This model is available with ASTM E18-20 certification

Rockwell Hardness & Superficial Rockwell Hardness Tester Scale/Indentor/Load Chart:

| Scale Symbol | Indentor Type | Preliminary Force N (kgf) | Total Force N (kgf) | Similar to A C and D scales but for thinner gage material

Typical Applications |

|---|---|---|---|---|

| 15N | Spheroconical Diamond | 29.42 (3) | 147.1 (15) | |

| 30N | Spheroconical Diamond | 29.42 (3) | 294.2 (30) | |

| 45N | Spheroconical Diamond | 29.42 (3) | 441.3 (45) | |

| 15T | 1/16” Carbide Ball | 29.42 (3) | 147.1 (15) | Similar to B, F and G scales but for thinner gage material. |

| 30T | 1/16” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45T | 1/16” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15W | 1/8” Carbide Ball | 29.42 (3) | 147.1 (15) | Very Soft Material |

| 30W | 1/8” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45W | 1/8” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15X | ¼” Carbide Ball | 29.42 (3) | 147.1 (15) | |

| 30X | ¼” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45X | ¼” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15Y | ½” Carbide Ball | 29.42 (3) | 147.1 (15) | |

| 30Y | ½” Carbide Ball | 29.42 (3) | 294.2 (30) |

HARNDESS TESTING RESOURCES:

- REBUILT INVENTORY W/ FULL WARRANTY

- PHASE II WARRANTY CARD

- PHASE II SAMPLE EVALUATION SHEETS

- HARDNESS TESTER CONVERSION CHART

- PRINCIPLE OF ROCKWELL HARDNESS TESTING

- ROUNDNESS CORRECTION CHART FOR HARNDESS TESTING

- PORTABLE HARDNESS TESTERS

- MINIMUM THICKNESS CHART FOR ROCKWELL HARDNESS TESTING

- ROCKWELL HARDNESS SCALE INDENTOR LOAD CHART

- NIST LINKS

- NIST SCALE HISTORY

- ASTM LINKS