ENG / 中文

Helpline:201-962-7373

Superficial Rockwell Hardness Tester Tallboy

Model No. 900-349

Features

- 16″/400mm workpiece height testing capacity

- Fully automated load/unload procedures affords highly sensitive and accurate readings

- Micro computer controlled with USB output to built-in mini printer or PC.

- Offers programmable scale conversions, dwell times, statistical capabilities and test counter

- Capable of testing in all of the Superficial Rockwell® hardness scales

This digital Superficial Rockwell hardness tester with fully automated load/unload procedures affords highly sensitive and accurate readings. Micro computer controlled with USB output to built-in mini printer or PC. Utilizing the guidelines of ASTM E-18, the 900-349 digital superficial Rockwell hardness tester offers programmable scale conversions, dwell times, statistical capabilities and test counter. Capable of testing in all of the superficial Rockwell® scales.

For full conformance to the latest E18-20 specification, please call (201) 962-7373

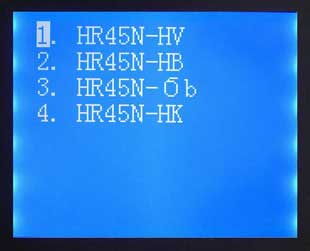

Automatic conversions to: Scale conversion, HV, HB, HK, σb.

Features:

- Fully automated load/unload procedures affords highly sensitive and accurate readings

- Micro computer controlled with USB output to built-in mini printer or PC.

- Offers programmable scale conversions, dwell times, statistical capabilities and test counter

- Capable of testing in all of the Superficial Rockwell® hardness scales

- Automatic conversions to Scale conversion, HV, HB, HK, σb

- Easily obtain Average, Min/Max, S, R

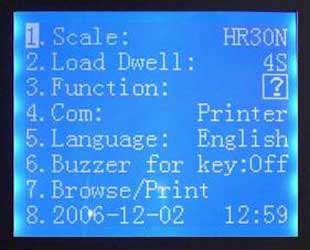

- Menu selectable system

- Upper/Lower Limit Settings

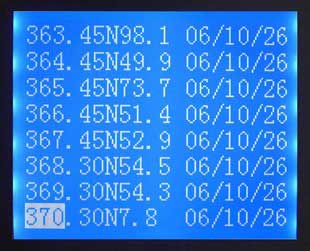

- Memory of 500 test results

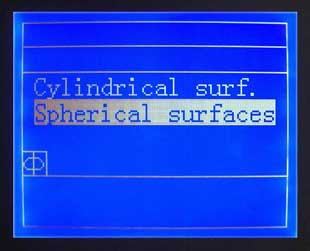

- Curved Surface Auto correction

Superficial Rockwell Hardness Tester Specifications:

| Minor Load | 3 Kgf |

|---|---|

| Major Load | 15 Kgf, 30 Kgf, 45 KGF |

| Test Force Application | Dead Weight |

| Test Force Control | Motorized |

| Results Display | Hi Def LCD Digital Readout |

| Resolution | 0.1HR |

| Vertical Capacity | 16.5″ |

| Memory/Output | 500 Tests/USB |

| Throat Depth | 6.50″ |

| Height | 28.34″ |

| Width | 7.87″ |

| Depth | 21.60″ |

| Weight | 220 lbs. |

Standard Accessories:

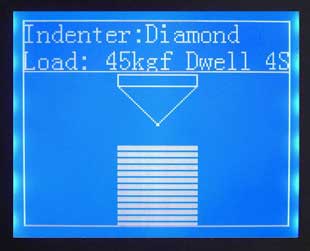

- N-scale Diamond Indentor

- 1/16″ Steel Ball Indenter

- Test Table 5.87″ (150mm)

- Flat Anvil 2.5″ (63mm)

- Std. Vee Anvil

- Accessory Case

- Dust Cover

- Dust Cover

- 3 pieces-HRN test blocks

- 3 pieces-HRT test blocks

Options:

- NIST/ASTM certified hardness test blocks, penetrators and kits are available.

- This model is available with ASTM E18-20 certification

Key performance parameters

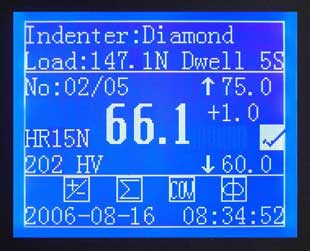

- Preload: 3kgf (29.4N) Total test force: 15kgf (147.1 N), 30kgf (294.3N), 45kgf (441.3 N)

- Scales: HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y, HR45Y

- Load cycle: 3~8s

- Load dwell duration: 2~50sLCD

- Resolution: 0.1HR

- Display: High definition LCD w/Backlight

- Operation: Menu selectable, Membrane keypad

- Auxiliary functions: Upper/lower limits setting& alarming,

- Data statistics, Avg., Max., Min., S, R,

- Scale conversion, HV, HB, HK, σb,

- Curved surface Auto Correct

- Data output: USB data output to PC, Integrated printer

- Memory: Max 500 items of test results stored automatically

- Testing space: 200mm in vertical, 165mm in horizontal

- Dimensions: 550mm×200mm×720mm

- Power supply: single phase, AC, 110V, 50~60Hz, 4A

- Net weight: 85kg

Prior to ship, please advise power setting needed.

Hardness Scales

Data Statistics

Scale Conversions

Automatic Surface Corrections

Browse or print memory

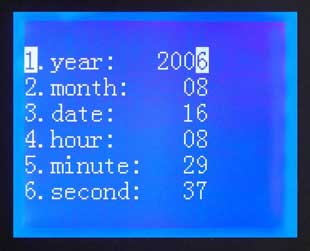

Set Time/Date & Year

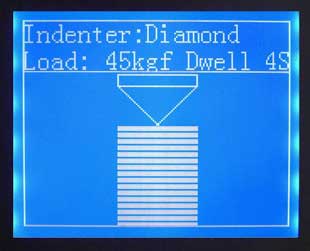

Display when Loading

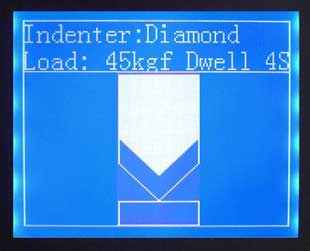

Display when Unloading

Rockwell Hardness & Superficial Rockwell Hardness Tester Scale/Indentor/Load Chart:

| Scale Symbol | Indentor Type | Preliminary Force N (kgf) | Total Force N (kgf) | Similar to A C and D scales but for thinner gage material

Typical Applications |

|---|---|---|---|---|

| 15N | Spheroconical Diamond | 29.42 (3) | 147.1 (15) | |

| 30N | Spheroconical Diamond | 29.42 (3) | 294.2 (30) | |

| 45N | Spheroconical Diamond | 29.42 (3) | 441.3 (45) | |

| 15T | 1/16” Carbide Ball | 29.42 (3) | 147.1 (15) | Similar to B, F and G scales but for thinner gage material. |

| 30T | 1/16” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45T | 1/16” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15W | 1/8” Carbide Ball | 29.42 (3) | 147.1 (15) | Very Soft Material |

| 30W | 1/8” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45W | 1/8” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15X | ¼” Carbide Ball | 29.42 (3) | 147.1 (15) | |

| 30X | ¼” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45X | ¼” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15Y | ½” Carbide Ball | 29.42 (3) | 147.1 (15) | |

| 30Y | ½” Carbide Ball | 29.42 (3) | 294.2 (30) |

HARNDESS TESTING RESOURCES:

- REBUILT INVENTORY W/ FULL WARRANTY

- PHASE II WARRANTY CARD

- PHASE II SAMPLE EVALUATION SHEETS

- HARDNESS TESTER CONVERSION CHART

- PRINCIPLE OF ROCKWELL HARDNESS TESTING

- ROUNDNESS CORRECTION CHART FOR HARNDESS TESTING

- PORTABLE HARDNESS TESTERS

- MINIMUM THICKNESS CHART FOR ROCKWELL HARDNESS TESTING

- ROCKWELL HARDNESS SCALE INDENTOR LOAD CHART

- NIST LINKS

- NIST SCALE HISTORY

- ASTM LINKS