ENG / 中文

Helpline:201-962-7373

Digital Brinell Hardness Tester/Brinell Hardness Testing

Model No. 900-355A is our newly designed Brinell hardness tester

The New 900-355A Brinell hardness tester is mainly used for Brinell hardness determination for metallic materials such as cast iron, steel profiles, nonferrous metals and soft alloys. It also can be used for Brinell testing of hard plastics, bakelite and some other nonmetallic materials. This Brinell Hardness Tester is suitable for use in factories, workshops, laboratories, universities and research institutes.

The Brinell Hardness Tester conforms to guidelines for:

- ISO6506 Metallic Materials-Brinell Hardness Test

- ASTM E-10 Test Method for Brinell Hardness of Metallic Materials

Brinell Hardness Tester Performance parameters

Test force: 3000kgf (29400N), 1500Kgf (14700N), 1000Kgf (9800N), 750Kgf(7355N),500Kgf (4900N), 250Kgf (2452N), 187.5Kgf (1839N), 125Kgf (1226N), 100Kgf (980N), 62.5Kgf(612.9N)

- Load dwell duration: 2s~99s, can be set and stored

- Tungsten Carbide Ball indenters: 10mm, 5mm, 2.5mm

- Measuring range: 8HBW~650HBW

- Magnification of the microscope: 20X

- Resolution capability of the microscope: 0.005mm

- Testing Capacity: 9.44” (240 mm) vertical, 6.10” (155mm) Throat Depth

- Dimensions: 550mm×210mm×780mm

- Net weight: 242lbs (110kg)

- Power supply: single phase, AC, 110V, 50~60Hz, 4A

- Conversions to popular hardness scales can be selected on the touch screen

Lighted Microscope and Large 8” Flat Anvil Included!

Brinell Hardness Tester Specifications:

- Innovative closed-loop technology. The 900-355A Brinell hardness tester incorporates the latest load cell technology. The test load is applied via a closed-loop control unit with a load cell, a DC motor and an electronic measurement and control unit. The result is highly accurate Brinell hardness measurements at all test loads up to 0.5%. The common load overshoot or undershoot as known from traditional dead weight, or open-loop, systems is eliminated. The absence of mechanical weights not only eliminates friction problems but also makes the equipment less sensitive to misalignments caused by vibrations.

- The whole weight of the Brinell Hardness tester is 50% less than the traditional dead weights type tester.

- Test load selection by keyboard and LCD screen.

- Fully automatic test cycles. The Brinell hardness Tester features a fully automatic test cycle, load application, holding, unloading, and is performed fully automatically. This greatly improves reproducibility of test results since operator influence is eliminated.

- Selectable dwell times by screen. The indenter, load, and other test information are shown clearly on the large LCD screen.

- The directions for 0.102F/D2 ratios selecting according to the materials and hardness range can be shown on the screen.

- Equipped with a 20X optical microscope with light supply to measure the diameter of Brinell indention

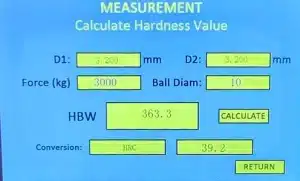

- Brinell Hardness Calculator (BHC) makes the Brinell hardness value calculation easy and convenient.

HARNDESS TESTING RESOURCES:

- REBUILT INVENTORY W/ FULL WARRANTY

- PHASE II WARRANTY CARD

- PHASE II SAMPLE EVALUATION SHEETS

- HARDNESS TESTER CONVERSION CHART

- PRINCIPLE OF ROCKWELL HARDNESS TESTING

- ROUNDNESS CORRECTION CHART FOR HARNDESS TESTING

- PORTABLE HARDNESS TESTERS

- MINIMUM THICKNESS CHART FOR ROCKWELL HARDNESS TESTING

- ROCKWELL HARDNESS SCALE INDENTOR LOAD CHART

- NIST LINKS

- NIST SCALE HISTORY

- ASTM LINKS