ENG / 中文

Micro Vickers Hardness Tester w/ Fully programmable XYZ axis hardness testing/Automatic Vickers Hardness Testers

Model No. 900-505

Features

Our advanced line of Micro Vickers hardness testers are state-of-the-art, precise testing systems suitable for Vickers hardness analysis of metallic specimens in metallography laboratories or production environments.

- Designed to test in Vickers (HV) and Knoop (HK) hardness scales.

- Fully programmable & automatic Vickers and Knoop hardness testing

- All Vickers hardness models in this series are supplied with an Auto Turret.

- All Phase II Vickers hardness testers come standard with digital camera, camera adaptor tube, usb cabling and software

- All software will do hardness conversions on screen

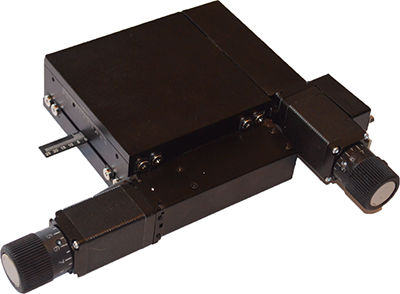

1. Motorized XY stage, standard size: 110mmX110mm table dimension, 25mmX25mm XY travel lengths

2. XYZ stepping drive box, with AC power cable, USB communication cable, XY motor cable, Z motor cable, and RS232 cable.

3. 1.3M Pixel USB 2.0 Camera (130-WOM)

4. Fully automatic Vickers software (USB dongle and software CD)

Our advanced line of Micro Vickers hardness testers are state-of-the-art, precise testing systems suitable for Vickers hardness analysis of metallic specimens in metallography laboratories or production environments.

The Phase II micro-vickers hardness testers are versatile and user-friendly systems, designed for the accurate Vickers and Knoop hardness testing of small precision parts, thin materials, coatings, wires and case depth determinations. The Phase II 900-505 micro-vickers hardness tester includes Automated X-Y-Z platform and controllers along with Auto-Turret, Video Cam, Adapter, USB Output Cable and Automatic Measurement Software. The 900-505 Micro Vickers hardness tester covers the load range from 10g to 1kg.

Conforming to ASTM E-384/92 vickers hardness testers standards, the 900-505 series micro vickers hardness testers will offer unmatched repeatability. This micro Vickers hardness tester can toggle back and forth between Vickers and Knoop measurement. A perfect rugged performer suited for any environment, the Phase II vickers hardness testers are offered with a 5 year warranty and free lifetime technical support.

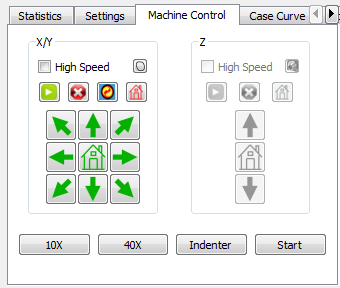

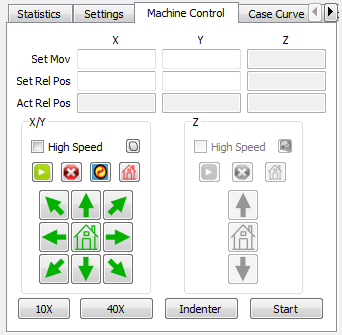

| Objective lens | 10× (observation) | 40× (measurement) |

|---|---|---|

| eyepiece | 10× | |

| Total magnification | 100× (observation) | 400× (measurement) |

| Measurement resolution | 0.0625μm | |

| Halogen brightness | 10 adjustable | |

Hardness Tester Specifications:

- 1. Test Forces: (gf) and (Nm)

10, 25, 50,100, 200, 300, 500, 1000(1K) gf

98, 245, 490, 980, 1960, 2940, 4900, 9800 Nm - 2. Test Scales:

Vickers Scales: HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1

Knoop Scales: HK0.01, HK0.025, HK0.05, HK0.1, HK0.2, HK0.3, HK0.5, HK1 - 3. Test mode: HV / HK

- 4. Language: English / Chinese

- 5. Test force application: Automatic –Loading-Dwell-Unloading

- 6. X-Y-Z Testing Table a) Dimension: 100×100mm b) Travel: 25×25 mm c) Revolving power: 0.002mm

- 7. Selection of hardness scale conversions

- 8. Dwell time of the test force: 0~90s (5 sec increments)

- 9. Turrett: Toggle between indenters and objectives: Automatic and manual selectable

- 10. Brightness: adjustable

Currently the system provides 14 programmable pattern types:

- Line;

- Line Set;

- Free Click;

- Horizontal Line;

- Vertical Line;

- Curve Line Sets;

- Curve Matrices;

- Arc;

- Gear Fillet;

- Gear Top Parallel;

- Auto Line Sets;

- Auto Matrices ;

- Circle Center;

- Curve Gear Top Parallel