ENG / 中文

Helpline:201-962-7373

Fully Automatic Universal Hardness Tester

Model No. 900-450

Features

The test force is applied via a closed-loop control unit with a load cell, a DC motor and an electronic measurement and control unit that replace traditional dead weights. The result is highly accurate measurements at all test loads up to 0.5%.

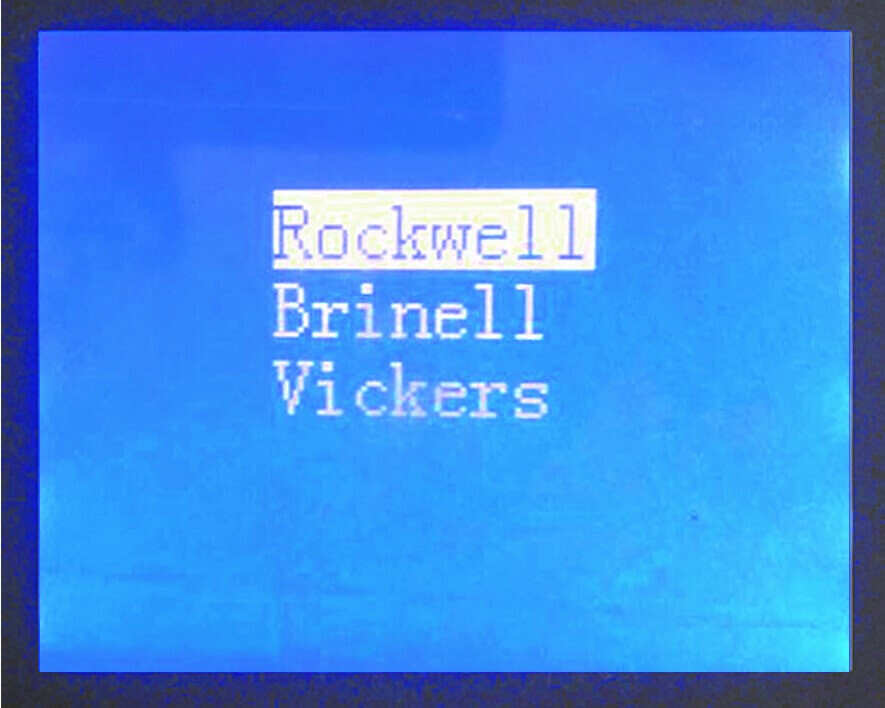

- Rockwell, Brinell and Vickers Universal Hardness Tester

Rockwell, Brinell and Vickers Univeral Hardness Tester

- The hardness test force is applied via a closed-loop control unit with a load cell, a DC motor and an electronic measurement and control unit that replace traditional dead weights. The result is highly accurate hardness test measurements at all test loads up to 0.5%.

- Simple plug – and – play tech allows for much more quick and easy installation than traditional dead weight type hardness testing machines.

- Automated Z-Axis .Just press START key once, entire hardness test process will be finished automatically. regardless of the size of the sample, the position of the sample, the distance between the indenter and sample surface. The sample will be auto-lifted to approach the indenter and finish hardness testing automatically.

- Higher precision than handle wheel lifting/dead weight type hardness machines which can be affected by user interaction.

- Extended dolphin nose allows vertical test height of 11.8” and throat depth of 8.6”.

- Built-in micro-printer.

Basic hardness tester functions:

- Twin hardness tester–Regular Rockwell & Superficial Rockwell hardness testing for metal and plastic material.

- Horizontal dolphin nose Indenter is suitable also for internal and external hardness testing.

- Rockwell hardness testing on Surfaces difficult to reach. Testing internal surface of rings and tubes.

- Advanced Rockwell hardness tester with many features such as high precision measuring, wide measuring range with 30 Rockwell hardness scales.

- The rockwell hardness tester is suitable for testing of carbon steel, alloy steel, cast iron, non ferrous metal.

- Automatic hardness testing cycle: Lifting of part, pre-loading, loading, dwell, unloading, results will be finished automatically.

- Rockwell hardness Test Measuring results and conversions, digitally displayed and can be printed, or transmitted to external computer automatically via USB port.

- Hardness test HR value can be converted to the value of HB, HV, HK and σb value.

- Utilizing the guidelines of ASTM E-18

ROCKWELL Hardness Parameters

- Preload: 29.4N(3kgf), 98.1N (10kgf)

- Total test force: 147.1N(15kgf), 294.3N(30kgf), 441.3N(45kgf), (superficial)

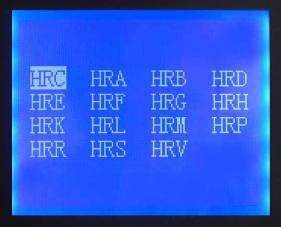

588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf) (Regular Rockwell) - Scales: HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y, HR45Y , HRA,HRB,HRC,HRD,HRE,HRF, HRG,HRH,HRK,HRL,HRM,HRP, HRR,HRS,HRV

BRINELL hardness parameters:

- Test force: 15.625kgf,31.25kgf, 62.5kgf,100kgf, 125kgf, 187.5kgf,250kgf

- Indenter: Φ2.5mm, Φ5mm, Φ10mm

- Scales: 2.5/187.5, 2.5/62.5, 2.5/31.25, 2.5/15.625, 5/250, 5/125, 5/62.5, 10/100, 10/250

VICKERS hardness parameters:

- Test force: 3kgf,10kgf,20kgf,30kgf,50kgf,100kgf

- Indenter: 136°diamond pyramid

- Scales: HV3,HV10,HV20,HV30,HV50,HV100

Other Important Hardness Tester Parameters:

- Load dwell duration: 2~50s, can be set and stored

- Resolution: 0.1HR

- Display: High definition backlight LCD

- Operation: Menu selectable, Membrane keypad

- Limit setting: Upper/lower limits setting & alarming

- Data statistics: Avg., Max., Min., S, R

- Curved surface auto correction

- Memory: Max 400 items of test results stored automatically

- Testing Capacity: 300mm (vertical) , 220mm (horizontal)

- Dimensions: 690mm×280mm×860mm

- Power supply: AC, 220V/110V, 50~60Hz, 4A (convertible)

- Net weight: 86 kg (190lbs)

- Gross weight: 120kg (265 lbs)

Included Accessories:

| Host machine span | 1 |

|---|---|

| Standard hardness block for B scale | 1 |

| Standard hardness block for C scale | 3 |

| Standard hardness block for 30N scale | 1 |

| Standard hardness block for 30T scale | 1 |

| ball indenter (1/16″) | 1 |

| 120°cone diamond indenter | 1 |

| Standard hardness block for HBW2.5/187.5 | 1 |

| Standard hardness block for HBW5/250 | 1 |

| Φ2.5mm Ball indenter | 1 |

| Φ5mm Ball indenter | 1 |

| 40X Microscope for Brinell | 1 |

| Standard hardness block HV10 | 1 |

| Standard hardness block HV30 | 1 |

| 136° diamond pyramid indenter | 1 |

| Microscope with 40X, 100X, 200X lens for Vickers | 1 |

| Camera and Specific Software for Vickers with USB-key | 1 |

| Φ150mm Flat anvil | 1 |

| “V ”shape anvil | 1 |

| Power supply wire | 1 |

| Mounting screws for indenter | 1 |

| Screwdriver for indenter mounting | 1 |

| Dust cover | 1 |