ENG / 中文

Ultrasonic Thickness Gauge Transducers/Probes Specifications:

| Part Number | UTG4000-400 | UTG2800-750 | UTG2600-400 | UTG2000-440 | UTG2000-450 | UTG2800-400 |

|---|---|---|---|---|---|---|

| Probe Style | Standard | Small Tube | Extreme small tube | Rough surface/Porous Metal | Hi-Temp | Standard |

| Frequency | 5MHz (E-E) | 7.5 MHz | 10 MHz | 2 MHz | 5 MHz | 5MHz |

| Contact Dia. | 8mm | 6mm | 4mm | 17mm | 15mm | 10mm |

| Measure range | .031-8.0” | .031-1.18” | .030-.787” | .157-20” | .157-3.14” | .040-12” |

| Temperature | 14-158ºF | 14-158ºF | 14-158ºF | 14-158ºF | 0-572ºF | 14-158ºF |

| Notes | Fits UTG-4000 only | Fits all models except UTG-2675 | Fits all models except UTG-2675 | Fits all models except UTG-2675 | Fits all models except UTG-2675 | Fits all models except UTG-2675 |

| Picture |  |

|

|

|

|

|

Ultrasonic Thickness Gauge Transducers/Probes Specifications:

| Part Number | UTG2900-400 | UTG2000-420 | UTG1500-400 | UTG2000-400 | UTG2650-400 | UTG2800-420 |

|---|---|---|---|---|---|---|

| Probe Style | Standard | Small Tube | Standard | Standard | Delay Line | Rough surface/Porous metal |

| Frequency | 5 MHz (E-E) | 5 MHz | 5 MHz | 5 MHz | 15 MHz | 2.5 MHz |

| Contact Dia. | 10mm | 6mm | 8mm | 12mm | 6mm | 17mm |

| Measure range | .031-23.0” | .031-1.18” | .040-8.0” | .040-8.0” | 0.010 to .787” | .157-20” |

| Temperature | 14-158ºF | 14-158ºF | 14-158ºF | 14-158ºF | 14-158ºF | 14-158ºF |

| Notes | Fits all models except UTG-2675 | Fits all models except UTG-2675 | Fits all models except UTG-2675 | Fits all models except UTG-2675 | Fits UTG-2650 and UTG-2675 only | Fits all models except UTG-2675 |

| Picture |  |

|

|

|

|

|

Table of basic sound velocity of various materials:

| Material | Sound velocity (m/s) |

|---|---|

| Aluminum | 6260 |

| Iron | 5900 |

| Copper | 4700 |

| Brass | 4640 |

| Zinc | 4170 |

| Silver | 3600 |

| Gold | 3240 |

| Tin | 3230 |

| Glass | 2350 |

UTG1000-850 Couplant Gel 5-Liter:

UTG1000-808 Couplant Gel 8oz:

- Water based and water soluble

- Slow drying with good transducer lubrication

- Extended ambient temperature range

- Stable couplant that holds on a vertical and

- overhead surfaces and fills depressions in rough surfaces

- MSDS available by request

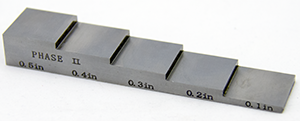

UTG-0500 5-Step Calibration Block:

- 1018 Steel

- .100″ thru .500″

The use of Ultrasonic non-destructive testing (NDT) to check material properties such as thickness measurement, is now extensively used in all facets of industry. The ability to gauge thickness measurement without requiring access to both sides of the test piece, offers this technology a multitude of possible applications. Metals, plastics, ceramics, glass and other materials can easily be measured by portable ultrasonic thickness gauges with a common accuracy of.001″.

Ultrasonic thickness gauges measure the thickness of a part by measuring the time sound travels from the transducer through the material to the back end of a part, and then measures the time of reflection back to the transducer. The gauge then calculates the thickness based on the velocity of sound through the material being tested.

A broad variety of piezoelectric transducers, operating at given frequencies are utilized to generate sound when excited. Typically, a 5mhz frequency is standard on all Phase II Ultrasonic Thickness Gauges. Optional transducers are always available for a myriad of applications.

The direct contact method of pulse/echo type ultrasonic thickness gauges requires use of a couplant. Propylene Glycol is common, but many other substances can be used.

Easy to configure and use, many gauges today have the ability to retain memory, output to printers, PC’s, and handheld portable devices. With the combination of an easy menu driven gauge and the data in memory, technician/operators have a world of technology at their fingertips to obtain highly accurate and cost effective measurements for all types of thickness applications.