Mini Surface Roughness Testers / Profilometer/ Surface Roughness Gage

Model No. SRG-2200

Features

The New Phase II SRG-2200 Mini Surface Roughness Tester is a next generation of surface roughness tester developed by the Phase II Metrology Group that features high accuracy, a wide range of application, simple operation and stable performance. It is widely applicable in surface roughness testing all kinds of metals and non-metals.

Large memory with data output via Bluetooth.

The 1.14″ IPS TFT display shows choice of surface roughness parameter Ra, Rz, Rq and Rt at the touch of a button, combined with the selected cutoff length.

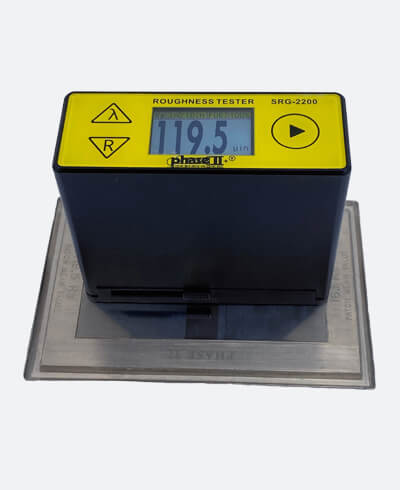

Surface Roughness Tester/profilometer shown w/ Optional Vise

Parameters: Ra, Rms, Rt and Rz

SRG-2200 Surface Roughness Tester/profilometer

The New Phase II SRG-2200 Mini Surface Roughness Tester/profilometer is a next generation of surface roughness tester/profilometer developed by the Phase II Metrology Group that features high accuracy, a wide range of application, simple operation and stable performance. It is widely applicable in surface roughness testing all kinds of metals and non-metals.

Large memory with data output via Bluetooth.

The 1.14” IPS TFT display shows choice of surface roughness parameter Ra, Rz, Rq and Rt at the touch of a button, combined with the selected cutoff length. External calibration of the surface roughness value is possible by means of a built-in calibration feature which makes adjustment of this instrument very easy. Data output via Bluetooth makes saving surface roughness results fast and easy.

The easy to use SRG-2200 surface roughness tester/profilometer operates on various surfaces, not only flat but also outer cylinder, outer cone, grooves, and recesses greater than 80x 30mm. The areas of application are wide-spread. It is suitable for inspection departments, quality control, on the shop floor during machining, during assembly, and on site.

The PHASE II SRG-2200 surface roughness tester/profilometer comes complete with a compact durable carrying case, surface roughness standard, data output software and instruction manual.

Specifications:

| Roughness parameter | Ra, Rms(Rq), (ISO), Rt, Rz (DIN) |

|---|---|

| Measuring range | Ra: 0.05-10.0µm / Rz 0.1-50µm Rms: 0.05-10.0µm / Rt: 0.1-50µm |

| Display Type | 1.14” IPS TFT |

| Cut-off lengths | 0.01in., 0.03in., 0.10in (0.25, 0.80, 2.50mm) |

| Filter | Gauss Digital |

| Tracing length | 0.23in (6mm) |

| Evaluation Length | 1.25mm, 4.0mm, 5.0mm |

| Tracing speed | 0.04in/second (1.0mm/second) |

| Accuracy | +/- 12% of actual Value |

| Pick-up stylus | Piezo-electric |

| Tracer tip | Diamond, radius 10mm +- 2.5mm |

| Memory / Transmission | 500 Values / Bluetooth |

| Operating temperature | 32-104 degrees F (0-40 degrees C) |

| Power | 1pc 1.5v AA Battery |

| Contact force on probe | <0.5N |

| Static measuring force of sensor stylus | <0.16N |

| Dimensions | 73x28x62mm |

| Weight | 0.5lbs (220g) |

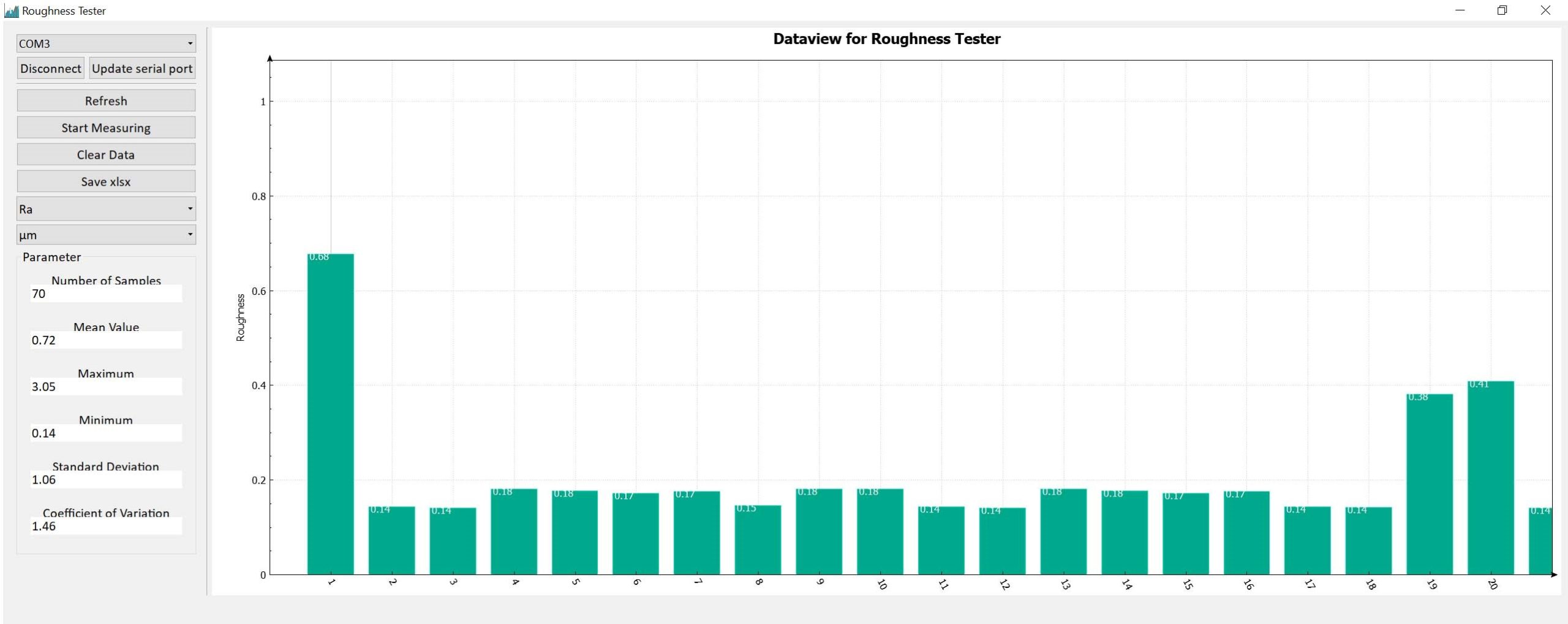

Data Output Software is Included!

Surface Roughness Testers/ Profilometer Measurement Guide

Surface roughness, for purposes of this forum, is the result of some machining process and its effect on the material surface in question.

Skid type surface roughness testers / profilometers are common instruments used on the shop floor. A diamond stylus is traversed across the specimen and a piezoelectric pickup records all vertical movement. Peaks and valleys are recorded and converted into a known value of a given parameter.

Parameters differ in how they approach looking at peaks and valleys. The most popular parameter is “Ra”. Ra is commonly defined as the arithmetic average roughness. While the Ra parameter is easy and efficient, there are other parameters that can be more specific and useful depending on the application requirements. It is the parameters that enable us to define surface roughness.

Today, for the purpose of checking Ra values, the use of portable, hand held, surface roughness testers /profilometers are not only economical, but are digital and easy to use. These surface roughness testers /profilometers are a given necessity for any shop floor that receives work with Ra surface finish requirements.