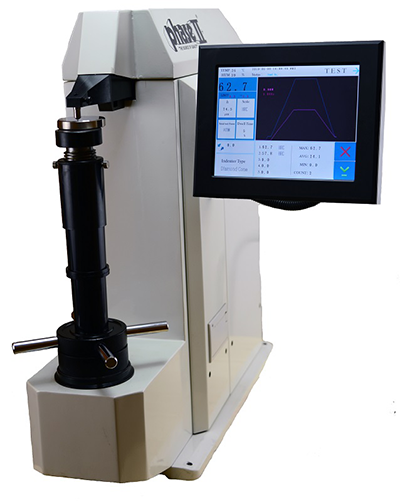

Digital Rockwell / Superficial Rockwell Hardness Testers/Hardness Testers/Rockwell Hardness Testers

Model No. 900-387

Features

- Reads in all Rockwell Hardness Scales and Superficial Rockwell Hardness Scales. These include the popular HRA, HRBW, HRC, HRN and HRT Hardness scales.

- Automatic conversions to all Rockwell/Superficial Rockwell Scales, as well as to Brinell (HB) and Vickers (HV).

- Touch Screen selectable system

- Upper/Lower Limit Settings

Load Cell, Closed Loop, Rockwell Hardness Tester!

Touch Screen Functions w/One Touch Testing Feature!

Features: Model No. 900-387 Rockwell Hardness Tester

This digital Rockwell/Superficial Rockwell hardness tester with fully automated load/unload procedures affords highly sensitive and accurate readings. Micro computer controlled Touch Screen with USB output to PC. Utilizing the guidelines of ASTM E-18, the 900-387 digital Rockwell hardness tester offers programmable scale conversions, dwell times, statistical capabilities and test counter. Capable of testing in all Rockwell/Superficial Rockwell Hardness Scales.

For full conformance to the latest E18-20 specification, please call (201) 962-7373

Direct Loading Method With Load-Cell Instead Of Dead Weight System. High Speed Test Cycle and Extremely Accurate Loading Control

- Automatic conversions to Rockwell, Superficial Rockwell, Brinell (HB) and Vickers (HV) Hardness Scales

- Touch Screen selectable system

- Upper/Lower Limit Settings

Specifications:Rockwell Hardness Tester

| Minor Load | 29.4N(3kgf), 98.1N (10kgf |

|---|---|

| Major Load | 147.1N(15kgf), 294.3N(30kgf), 441.3N(45kgf), 588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf) |

| Test Force Application | Load Cell Closed Loop |

| Test Force Control | Motorized |

| Results Display | Hi Def LCD Digital Readout |

| Resolution | 0.01HR |

| Vertical Capacity | 7.80” |

| Throat Depth | 5.90” |

| Height | 700mm |

| Width | 600mm |

| Depth | 250mm |

| Weight | 220 lbs |

Accessories: Included

-

- C/N scale Diamond Indenter

- 1/16” Ball Indenter

- 2- HRC Test Blocks

- 1- HRB Test Block

- 2- HRN Test Block

- 1- HRT Test Block

- Test Table 5.87″ (150mm)

- Flat Anvil 2.5″ (63mm)

- Std. V- Anvil

- Accessory Case

Test resolution: 0.01HR Rockwell unit;

Operation temperature: 50° – 95°F (10ᵒC~35ᵒC)

Ambient environment: clean, no vibration, no strong magnetic field, and no corrosive medium;

Power supply:single phase, AC, 110-220 with manual change, 50~60Hz, 4A;

Machine dimension: 700mm×250mm×600mm.

Options:

- NIST/ASTM certified hardness test blocks, penetrators and kits are available.

- This model is available with ASTM E18-20 certification

Rockwell Hardness & Superficial Rockwell Hardness Tester Scale/Indentor/Load chart

| Scale Symbol | Indentor Type | Preliminary Force N (kgf) | Total Force N (kgf) | Typical Applications |

|---|---|---|---|---|

| A | Spheroconical Diamond | 98.07 (10) | 588.4 (60) | Cemented carbides, thin steel, and shallow case hardened steel |

| B | 1/16” Carbide Ball | 98.07 (10) | 980.7 (100) | Copper alloys, soft steels, aluminum alloys, malleable iron, etc. |

| C | Spheroconical Diamond | 98.07 (10) | 1471 (150) | Steel, hard cast irons, pearlitic malleable iron, titanium, deep case hardened steel, other harder than HRB 100 |

| D | Spheroconical Diamond | 98.07 (10) | 980.7 (100) | Thin steel and medium case hardened steel, and pearlitic malleable iron |

| E | 1/8” Carbide Ball | 98.07 (10) | 980.7 (100) | Cast Iron, Aluminum and magnesium alloys, and bearing metals |

| F | 1/16” Carbide Ball | 98.07 (10) | 588.4 (60) | Annealed copper alloys and thin soft sheet metals |

| G | 1/16” Carbide Ball | 98.07 (10) | 1471 (150) | Malleable irons, copper-nickel-zinc and cupro-nickel alloys |

| H | 1/8” Carbide Ball | 98.07 (10) | 588.4 (60) | Aluminum, zinc and lead |

| K | 1/8” Carbide Ball | 98.07 (10) | 1471 (150) | Bearing Metals and other very soft or thin materials. Use smallest ball and heaviest load that doesn’t give anvil effect. |

| L | ¼” Carbide Ball | 98.07 (10) | 588.4 (60) | |

| M | ¼” Carbide Ball | 98.07 (10) | 980.7 (100) | |

| P | ¼” Carbide Ball | 98.07 (10) | 1471 (150) | |

| R | ½” Carbide ball | 98.07 (10) | 588.4 (60) | |

| S | ½” Carbide ball | 98.07 (10) | 980.7 (100) | |

| V | ½” Carbide ball | 98.07 (10) | 980.7 (150) | |

| 15N | Spheroconical Diamond | 29.42 (3) | 147.1 (15) | Similar to A, C and D scales but for thinner gage material. |

| 30N | Spheroconical Diamond | 29.42 (3) | 294.2 (30) | |

| 45N | Spheroconical Diamond | 29.42 (3) | 441.3 (45) | |

| 15T | 1/16” Carbide Ball | 29.42 (3) | 147.1 (15) | Similar to B, F and G scales but for thinner gage material. |

| 30T | 1/16” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45T | 1/16” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15W | 1/8” Carbide Ball | 29.42 (3) | 147.1 (15) | Very Soft Material |

| 30W | 1/8” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45W | 1/8” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15X | ¼” Carbide Ball | 29.42 (3) | 147.1 (15) | |

| 30X | ¼” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45X | ¼” Carbide Ball | 29.42 (3) | 441.3 (45) | |

| 15Y | ½” Carbide Ball | 29.42 (3) | 147.1 (15) | |

| 30Y | ½” Carbide Ball | 29.42 (3) | 294.2 (30) | |

| 45Y | ½” Carbide Ball | 29.42 (3) | 441.3 (45) |