December 2025 Products of the Month

Coating Thickness Gauges!

Model No. PTG-5500

Features:

The PHASE II PTG-5500 coating thickness gauge can perform two different methods of calculating coating thickness measurement by utilizing the characteristics of both eddy current and magnetic induction.

Coating thickness testing performance is both non-destructive and extremely accurate.

With this state of the art coating thickness gauge, you can easily detect the thickness of nonmagnetic coating on a magnetic substrate (ferrous) or an insulating coating on a non-magnetic conductive substrate (non-ferrous) utilizing our auto-detect probe

The PTG-5500 coating thickness gauge can be used in many areas of industry including automotive auctions, manufacturing, general engineering, commercial inspection, etc.

Probe type: Auto Detect: Ferrous/Non-Ferrous

Measuring principle: Magnetic induction Eddy current

Measuring range: 0~1500 um (0-59mil)0~1500 um (0-59mil)

Resolution (Selectable): 1 um , 0.1 um, .01um1 um , 0.1 um, .01um

Accuracy: Zero calibration: 2%H+1) um

Min. radius of curvature: ±1.5 mm(magnetic induction)

+/-3 mm (Eddy Current)

Measuring Condition:

Min. radius of area 7mm (magnetic induction) 5mm(eddy current)

Critical thickness of plate:0.5 mm(magnetic induction) 0.3 mm(Eddy Current)

Model No. PTG-4000

Features:

The PHASE II PTG-4000 coating thickness gauge can perform two different methods of calculating thickness measurement by utilizing the characteristics of both eddy current and magnetic induction.

Testing performance is both non-destructive and extremely accurate.

With this state of the art coating thickness gage, you can easily detect the thickness of nonmagnetic coating on a magnetic substrate (ferrous) or an insulating coating on a non-magnetic conductive substrate (non-ferrous) utilizing our auto-detect, integrated probe

The PTG-4000 coating thickness gauge can be used in many areas of industry including automotive auctions, manufacturing, general engineering, commercial inspection, etc.

- Measuring range:0-1,250 µm max. or 0-50 mils

- Resolution:1 µm / 0.1mils

- Accuracy:+/- 3% + 2 µm ( +/-3%+0.1 mil )

- Display: 3 digit color LCD

- Statistics: Min/Max, Average, Std Deviation

- Single or Continuous Measurement(Selectable)

- Min. measuring area: 0.2″ x 0.2″ (5mm x 5mm)

- Min. radius of curvature:Convex: 0.12″ (3mm) Concave: 1.2″ (30mm)

- Min. substrate thickness:Ferrous: 20 mils (0.5mm) Non-ferrous: 2 mils (50 µm)

- Max. Surface temperature of test object: 302 degrees F (contact time max is 2 seconds)

- Power source: 2-AAA batteries

See All Coating Thickness Gauges!

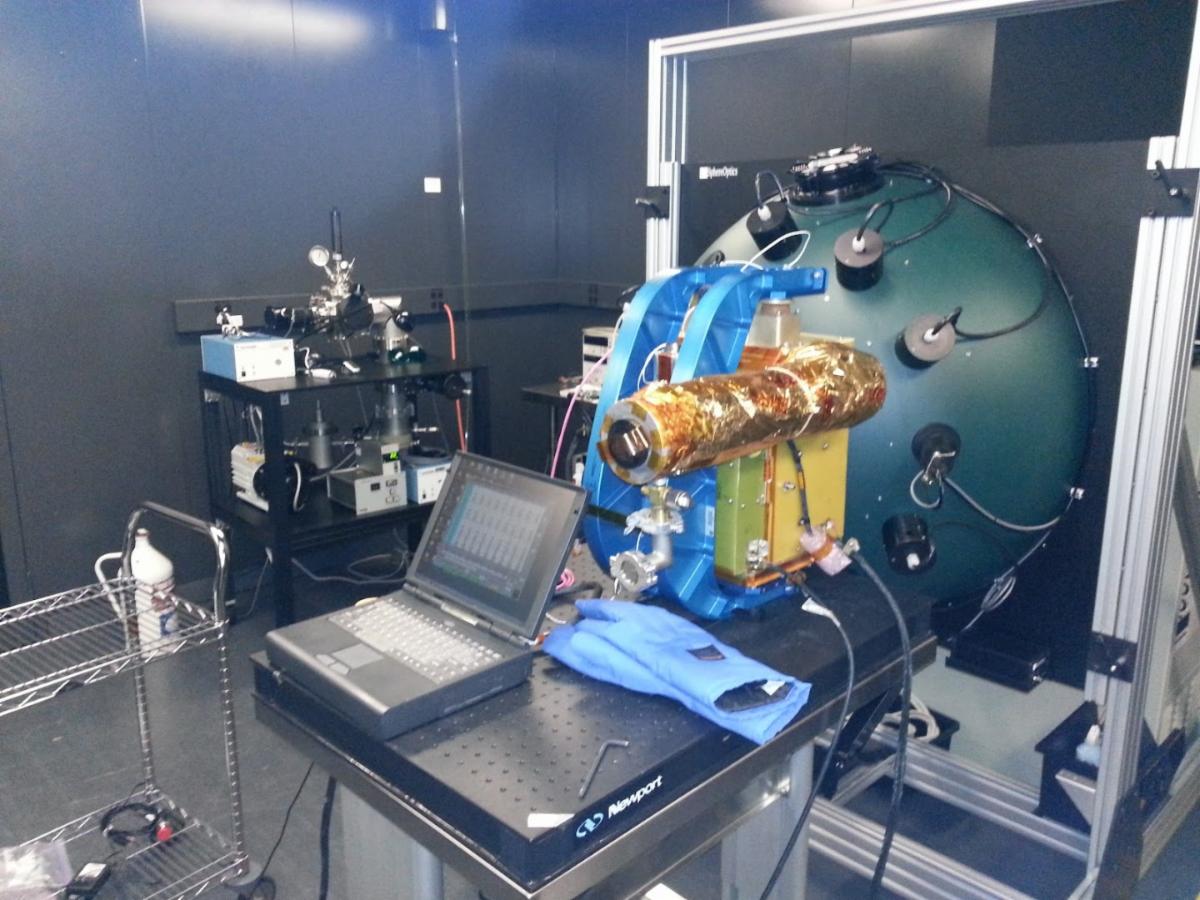

Calling All Calibration Labs!

Phase II is actively seeking partnerships with top-tier calibration laboratories around the world. By joining forces with us, your company will be featured on our esteemed list of trusted references, enhancing your visibility and credibility in the industry.

As a partner, you’ll receive:

- Comprehensive technical support for all Phase II instruments

- Exclusive access to our partner-only sales and discount programs

Take the first step—call us at

201-962-7373 and get set up today!

DISTRIBUTOR CORNER!

Attention Distributors: Planning an annual open house? Inform us of the date, time, and venue. Phase II is actively seeking partnerships with distributors to showcase our brand and products at local and/or regional industrial trade shows. Kindly share the event details with us at info@phase2plus.com

NOTICE: New Phase II MAPP pricing policy:

Product Spotlight!

PHT-1750 Portable Hardness Tester

for large rough castings in the Brinell scale.

Loaded with features, this economically priced portable hardness tester is capable of measuring the surface hardness of a broad variety of metals on flat and round surfaces. This portable hardness tester comes complete with the G impact device, calibrated HLG test block and rugged carry case.

Designed to test large cast parts and those with rough surfaces:

2025 Price List Now Available

NEW! Full Line Catalog Now Available

CHECK THESE PRODUCTS OUT!